Single Stage Vertical Mounted Parallel Shaft Helical Gearbox

Technical Parameters:

| Available Models | H1SH03~H1SH19, H1SV03~H1SV19, H1HH03~H1HH19, H1HV03~H1HV19, H1HM03~H1HM19, H1DH03~H1DH19, H1DV03~H1DV19, H1KH03~H1KH19, H1KV03~H1KV19, H1FH03~H1FH19 |

| Ratio | 1.25~450 |

| Input power | 5.5~4400 kW |

| Max torque | 2.9~900 kN.m |

DESCRIPTION

Single stage helical gearbox is specifically designed for fast rotating shafts such as roll-applications. The range includes gear unit sizes which are optimally divided to meet required torque ranges and ratio requirements. Integrated lubrication canals and gear wheels manufactured with high accuracy have resulted in compact dimensions with a high torque range from 1 to 400 k.Nm. Maintenance-free labyrinth seals are integrated into the gearbox housing. Labyrinth seals cause neither wear nor friction on the rotating shaft. The gearbox can be easily connected to a central lubrication system or gearboxes can be delivered with a separate lubrication unit.

CHARACTERISTICS

- Adopt optimized modular design.

- Parallel shaft output form.

- The transmission torque distribution curve is excellent, suitable for heavy load conditions.

- It adopts advanced grinding technology and shape modification technology, which has high bearing capacity, reliable operation and low noise.

- The box body is made of high-quality casting to improve the mechanical strength and seismic performance of the reducer.

- Numerous mounting options are available.

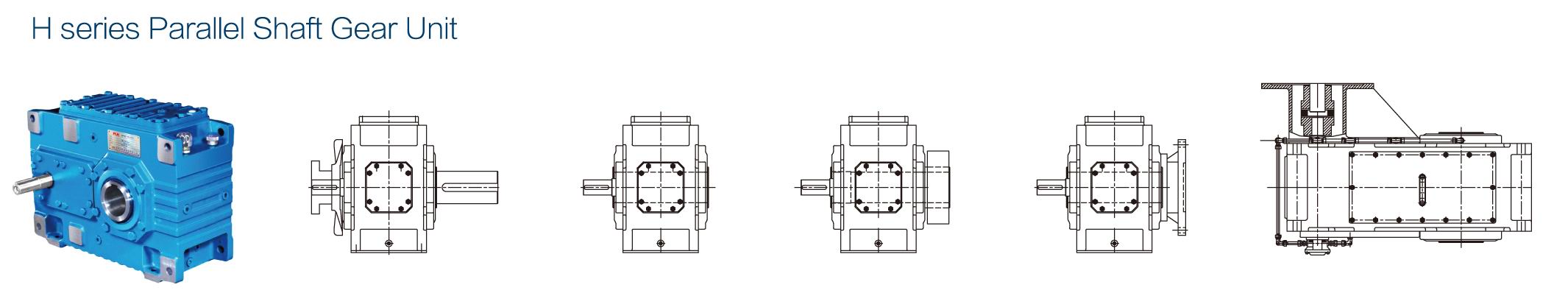

Product Form

- Transmission Stage: single stage, 2 stage, 3 stage, 4 stage.

- Mounting: Horizontal mounted, Vertical mounted

- Parallel Output: Solid shaft, Hollow shaft ( flat key, shrink disk, involute spline), Splined solid shaft, flanged shaft

- Configuration options: With auxiliary tank, with oil pump, with cooling fan, with backstop, with hydraulic coupling, with gear unit swing-base

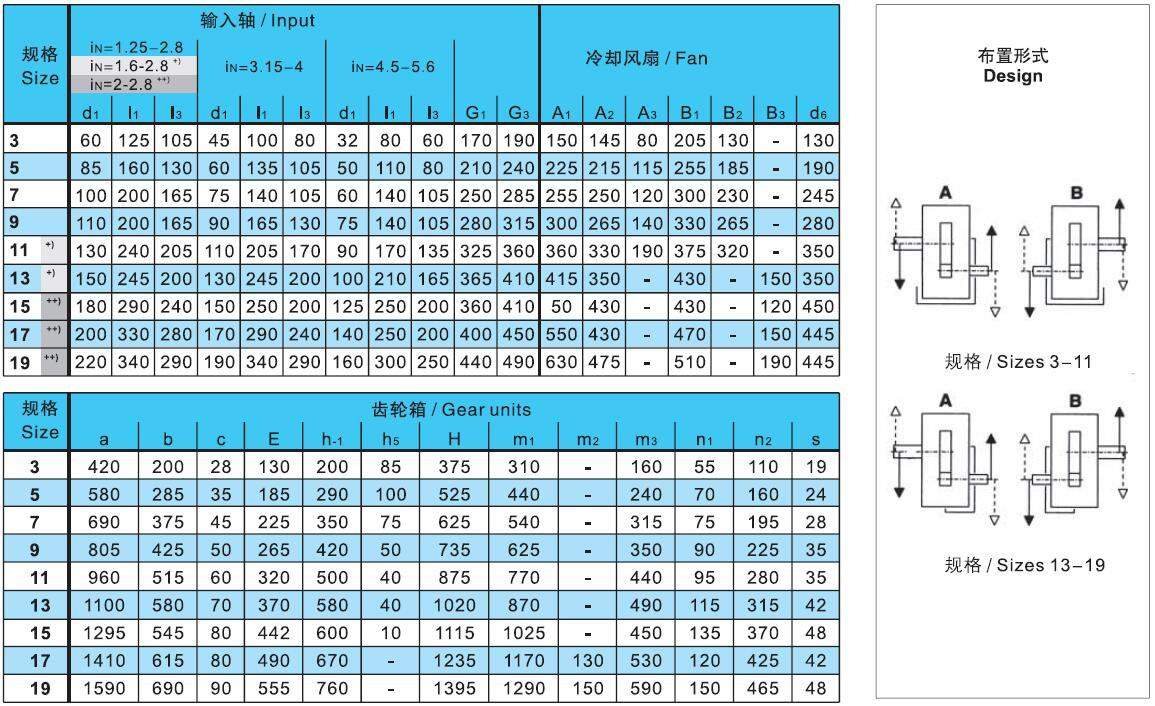

Technical Data

- Size: H1SH03~H4SH26

- Technical Data(kN·m): 2.9~900

- Gear Ratio: 1.25~450

- Input Power(kW):5.5~4400

Available Models

Single stage parallel shaft helical gear box models:

- H1SH03 gearbox, H1SH05 gearbox, H1SH07 gearbox, H1SH11 gearbox, H1SH13 gearbox, H1SH15 gearbox, H1SH17 gearbox, H1SH19 geabox,

- H1SV03 gearbox, H1SV05 gearbox, H1SV07 gearbox, H1SV11 gearbox, H1SV13 gearbox, H1SV15 gearbox, H1SV17 gearbox, H1SV19 gearbox,

- H1HH03 gearbox, H1HH05 gearbox, H1HH07 gearbox, H1HH11 gearbox, H1HH13 gearbox, H1HH15 gearbox, H1HH17 gearbox, H1HH19 gearbox,

- H1HV03 gearbox, H1HV05 gearbox, H1HV07 gearbox, H1HV11 gearbox, H1HV13 gearbox, H1HV15 gearbox, H1HV17 gearbox, H1HV19 gearbox,

- H1HM03 gearbox, H1HM05 gearbox, H1HM07 gearbox, H1HM11 gearbox, H1HM13 gearbox, H1HM15 gearbox, H1HM17 gearbox, H1HM19 gearbox,

- H1DH03 gearbox, H1DH05 gearbox, H1DH07 gearbox, H1DH11 gearbox, H1DH13 gearbox, H1DH15 gearbox, H1DH17 gearbox, H1DH19 gearbox,

- H1DV03 gearbox, H1DV05 gearbox, H1DV07 gearbox, H1DV11 gearbox, H1DV13 gearbox, H1DV15 gearbox, H1DV17 gearbox, H1DV19 gearbox,

- H1DM03 gearbox, H1DH5 gearbox, H1DH07 gearbox, H1DH11 gearbox, H1DH13 gearbox, H1DH15 gearbox, H1DH17 gearbox, H1DH19 gearbox,

- H1KH03 gearbox, H1KH05 gearbox, H1KH07 gearbox, H1KH11 gearbox, H1KH13 gearbox, H1KH15 gearbox, H1KH17 gearbox, H1KH19 gearbox,

- H1KV03 gearbox, H1KV05 gearbox, H1KV07 gearbox, H1KV11 gearbox, H1KV13 gearbox, H1KV15 gearbox, H1KV17 gearbox, H1KV19 gearbox,

- H1KM03 gearbox, H1KM05 gearbox, H1KM07 gearbox, H1KM11 gearbox, H1KM13 gearbox, H1KM15, H1KM17 gearbox, H1KM19 gearbox,

- H1FH03 gearbox, H1FH05 gearbox, H1FH07 gearbox, H1FH11 gearbox, H1FH13 gearbox, H1FH15 gearbox, H1FH17 gearbox, H1FH19 gearbox

- H1FV03 gearbox, H1FV05 gearbox, H1FV07 gearbox, H1FV11 gearbox, H1FV13 gearbox, H1FV15 gearbox, H1FV17 gearbox, H1FV19 gearbox,

- F1FM03 gearbox, H1FM05 gearbox, H1FM07 gearbox, H1FM11 gearbox, H1FM13 gearbox, H1FM15 gearbox, H1FM17 gearbox, H1FM19 gearbox,

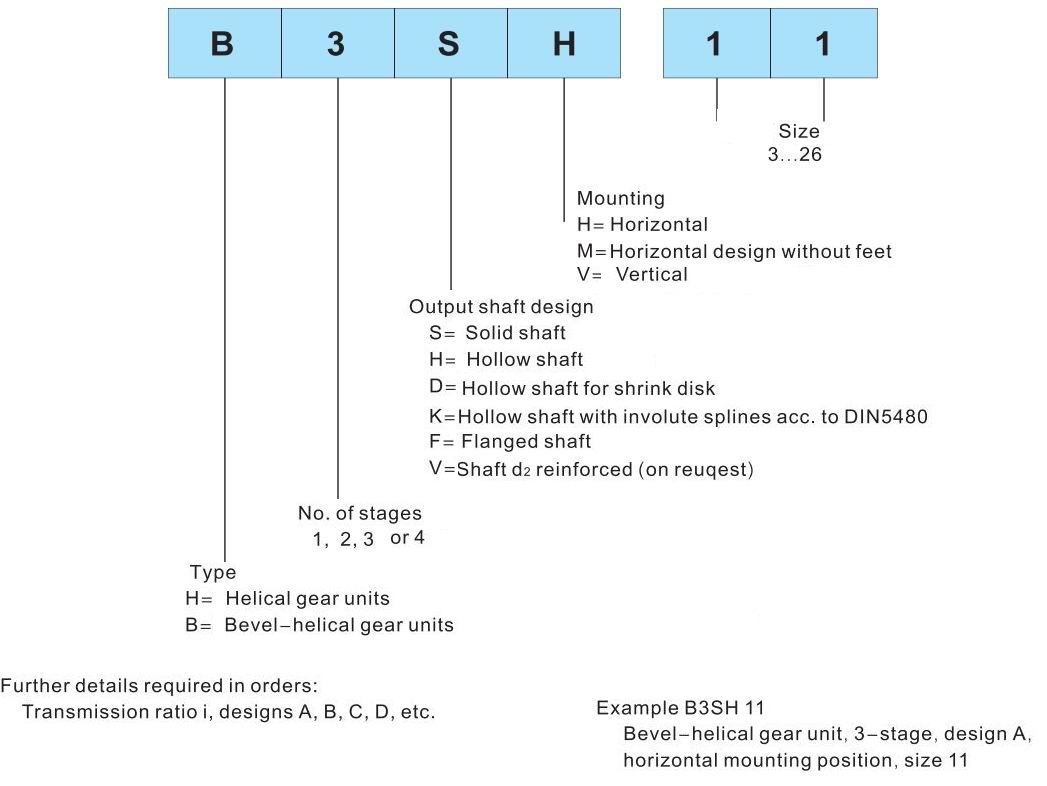

Type and Designation

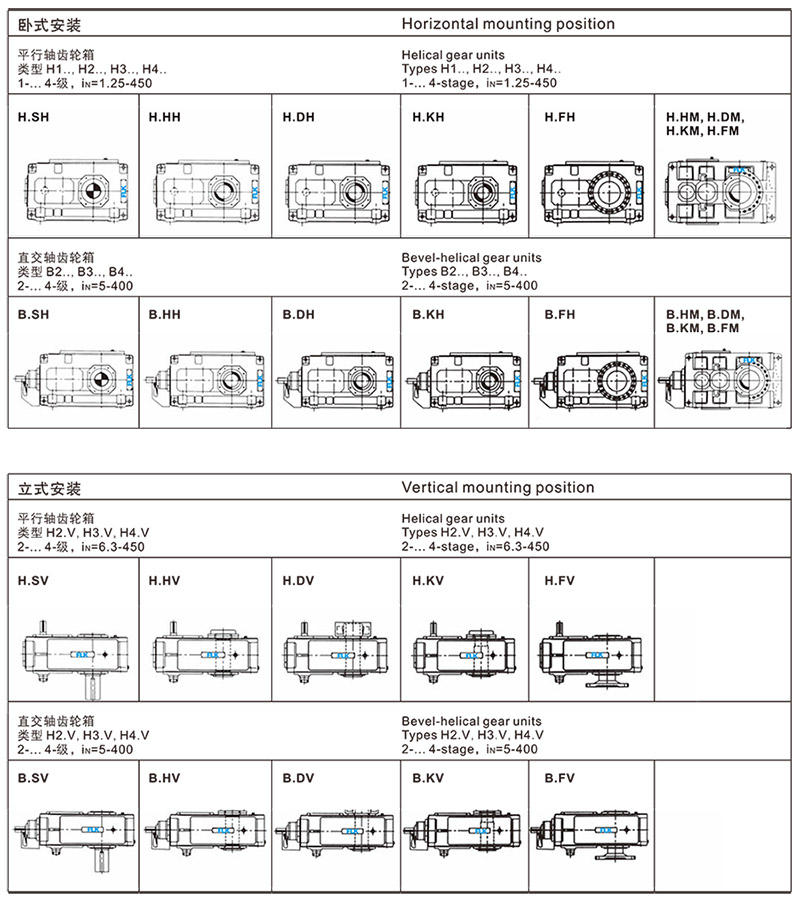

Mounting Position

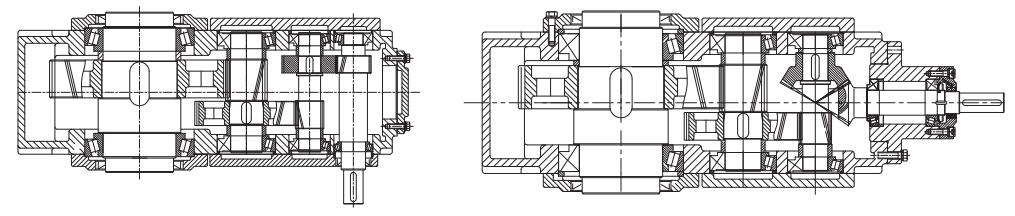

Structure Drawing

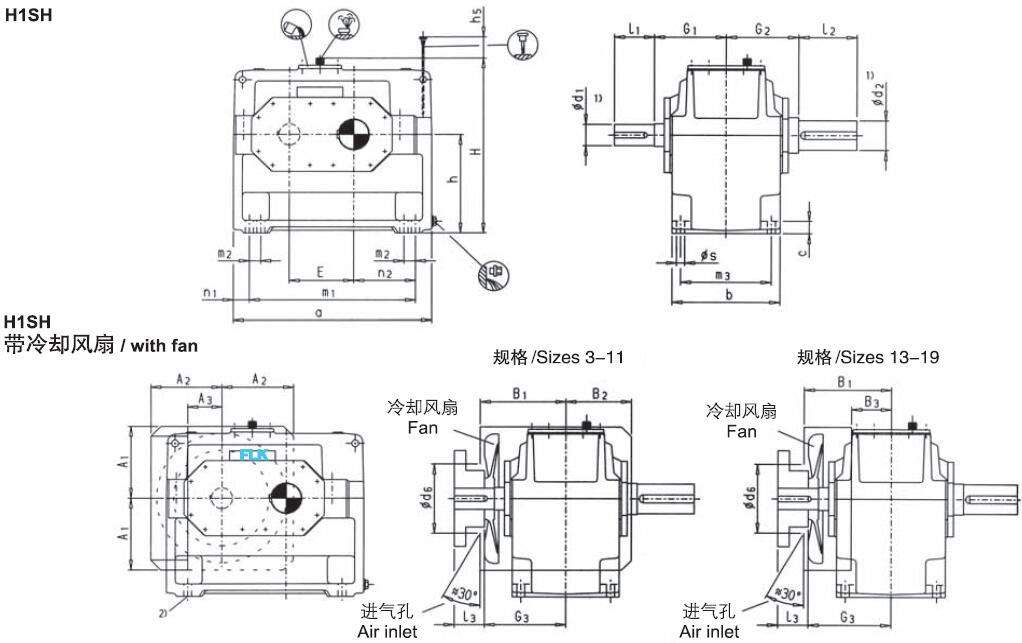

Single Stage Parallel Shaft Gearbox Drawing

MODULAR DESIGN

PRODUCT PICTURES

Application:

- Paper Machine Drives

- Drum Drives

- Pulper Drives

- Chipper Drives

- Conveyor Drives

- Crusher Drives

- Crane Drives

- Pump Drives

- Screening Drives

- Coiler Drives

- Roll Drives

- Vacuum pump drives

- Refiner drives

- Roll drives

- Blowers

- Crushers

- Chippers for wood yard