Parallelwellen-Stirnradgetriebe der H-Serie

Technische Parameter:

| Verfügbare Modelle | H1SH03~H4SH26 |

| Verhältnis | 1,25~450 |

| Eingangsleistung | 5,5~4400 kW |

| Maximales Drehmoment | 2,9~900 kN.m |

BESCHREIBUNG

Industrielle Stirnradgetriebe der H-Serie sind hochwertige Getriebe für schwere Industrieanwendungen. Alle mechanischen Teile werden mit modernster Software analysiert, um ihre Zuverlässigkeit zu gewährleisten. Wir bieten auch maßgeschneiderte Lösungen für spezifische Anwendungen an.

Hocheffiziente Schrägverzahnungs-Parallelwellen-Industriegetriebe der H-Serie wurden eingeführt, um den Anforderungen der heutigen anspruchsvollen Anwendungen im mittleren und schweren Bereich des Kraftübertragungsmarkts gerecht zu werden. Der Zweck des Einsatzes des Parallelwellengetriebes besteht darin, die Drehzahl zu reduzieren und das Drehmoment zu erhöhen. Es ist für Hochgeschwindigkeitsachsgeschwindigkeiten von nicht mehr als 1500 U/min, eine Umfangsgeschwindigkeit des Zahnradantriebs von nicht mehr als 20 m/s und eine Arbeitsumgebungstemperatur von -40℃~+45℃ geeignet. Die Getriebe sind kompakt, vollständig gekapselt und für die Direktmontage konzipiert, um einen hochpräzisen formschlüssigen Antrieb und eine dauerhafte Ausrichtung zu gewährleisten und so Platzbedarf und Layoutprobleme zu minimieren. Das Parallelwellen-Stirnradgetriebe der H-Serie bietet unbegrenzte Installationsflexibilität.

EIGENSCHAFTEN

- Übernehmen Sie ein optimiertes modulares Design.

- Ausgangsform mit paralleler Welle.

- Die Drehmomentverteilungskurve des Getriebes ist ausgezeichnet und eignet sich für schwere Lastbedingungen.

- Es verwendet fortschrittliche Schleiftechnologie und Formmodifikationstechnologie, die sich durch hohe Tragfähigkeit, zuverlässigen Betrieb und geringe Geräuschentwicklung auszeichnet.

- Der Kastenkörper besteht aus hochwertigem Guss, um die mechanische Festigkeit und seismische Leistung des Reduzierstücks zu verbessern.

- Es stehen zahlreiche Montagemöglichkeiten zur Verfügung.

Produktform

- Übertragungsstufe: einstufig, 2-stufig, 3-stufig, 4-stufig.

- Montage: Horizontal montiert, Vertikal montiert

- Paralleler Ausgang: Vollwelle, Hohlwelle (Flachfeder, Schrumpfscheibe, Evolventenverzahnung), Vollwelle mit Keilverzahnung, Flanschwelle

- Konfigurationsmöglichkeiten: Mit Zusatztank, mit Ölpumpe, mit Kühlgebläse, mit Rücklaufsperre, mit hydraulischer Kupplung, mit Getriebeschwinge

Technische Daten

- Größe: H1SH03~H4SH26

- Technische Daten (kN·m): 2,9–900

- Übersetzungsverhältnis: 1,25 ~ 450

- Eingangsleistung (kW): 5,5 ~ 4400

- Gehäusematerial: HT250 hochfestes Gusseisen

- Gehäusehärte: HBS190-240

- Getriebematerial: legierter Stahl 20CrMnTi, andere gewünschte Materialien: 17CrNi2Mo, 20CrNi4A

- Oberflächenhärte der Zahnräder: HRC58-62

- Härte des Getriebekerns: HRC33–40

- Material der Eingangs-/Ausgangswelle: 42CrMo-legierter Stahl

- Härte der Eingangs-/Ausgangswelle: HRC25–30

- Wärmebehandlung: Anlassen, Zementieren, Abschrecken usw.

- Bearbeitungspräzision der Zahnräder: präzises Schleifen, Güteklasse 6–5

- Lärm (MAX): 60 ~ 68 dB

- Schmieröl: GB L-CKC220-460, Shell Omala220-460

- Temp. Anstieg (MAX): 40°C

- Wirkungsgrad: 94 % ~ 96 % (abhängig von der Übertragungsstufe)

- Temp. Anstieg (Öl)(MAX): 50°C

- Spiel: ≤20Arcmin

- Vibration: ≤20 µm

- GLEICHE ABMESSUNGEN WIE Flender

Verfügbare Modelle

| H-Serie | Verhältnis | B-Serie | Verhältnis |

| H1 (1-stufiges Parallelwellengetriebe) | 1,25~5,6 | – | – |

| H2 (2-Stufen-Parallelwellengetriebe) | 6,3~28 | B2 (2-stufiges Kegelstirnradgetriebe) | 5~18 |

| H3 (3-Stufen-Parallelwellengetriebe) | 22,4~112 | B3 (3-stufiges Kegelstirnradgetriebe) | 12,5~90 |

| H4 (4-Stufen-Parallelwellengetriebe) | 100~450 | B4 (4-stufiges Kegelstirnradgetriebe) | 80~400 |

| Übertragungsstufe | Verhältnis(ich) | Modelle |

| H1 | 1,25 – 5.6 | H1SH3, H1SH5, H1SH7, H1SH9, H1SH11, H1SH13, H1SH15, H1SH17, H1SH19 |

| H2 | 6.3 – 28 | H2SH4, H2SH5, H2SH6, H2SH7, H2SH8, H2SH9, H2SH10, H2SH11, H2SH12, H2SH13, H2SH14, H2SH15, H2SH16, H2SH17, H2SH18, H2SH19, H2SH20, H2SH21, H2SH22, H2SH23, H2SH24, H2SH25, H2SH26 |

| H3 | 25 – 112 |

H3SH4, H3SH5, H3SH6, H3SH7, H3SH8, H3SH9, H3SH10, H3SH11, H3SH12, H3SH13, H3SH14, H3SH15, H3SH16, H3SH17, H3SH18, H3SH19, H3SH20, H3SH21, H3SH22, H3SH23, H3SH24, H3SH25, H3SH26 |

| H4 | 90 – 450 | H4SH5, H4SH6, H4SH7, H4SH8, H4SH9, H4SH10, H4SH11, H4SH12, H4SH13, H4SH14, H4SH15, H4SH16, H4SH17, H4SH18, H34H19, H4SH20, H4SH21, H4SH22, H4SH23, H4SH24, H4SH25, H4SH26 |

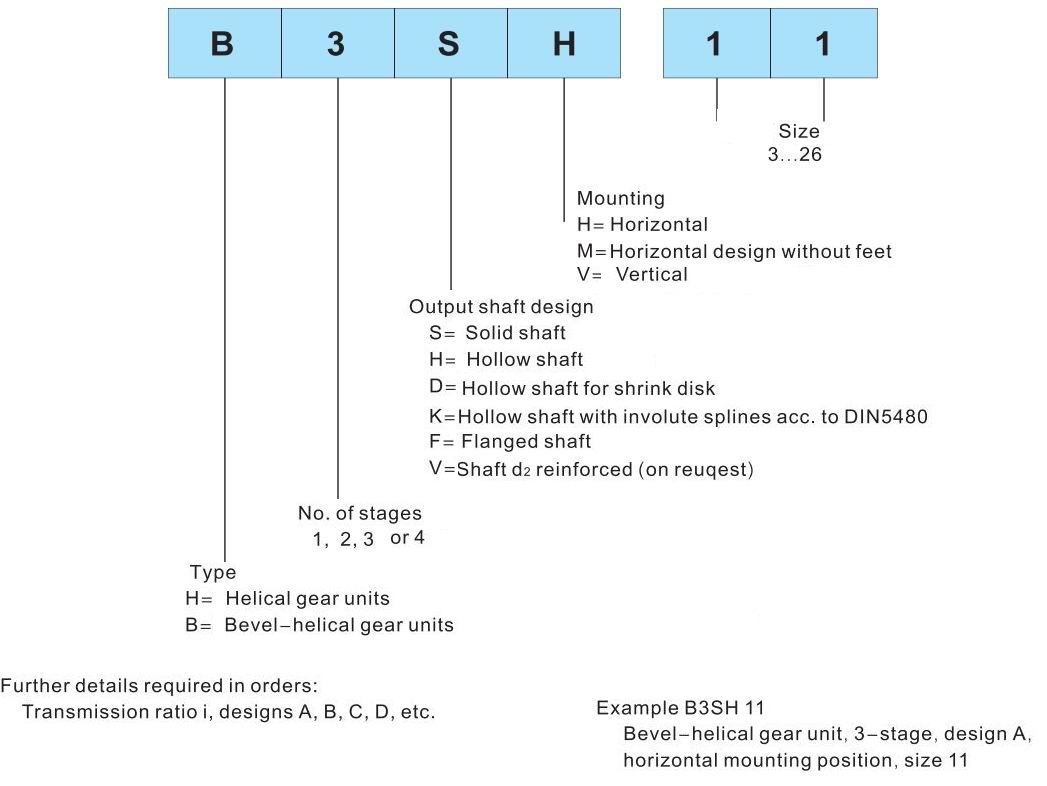

Typ und Bezeichnung

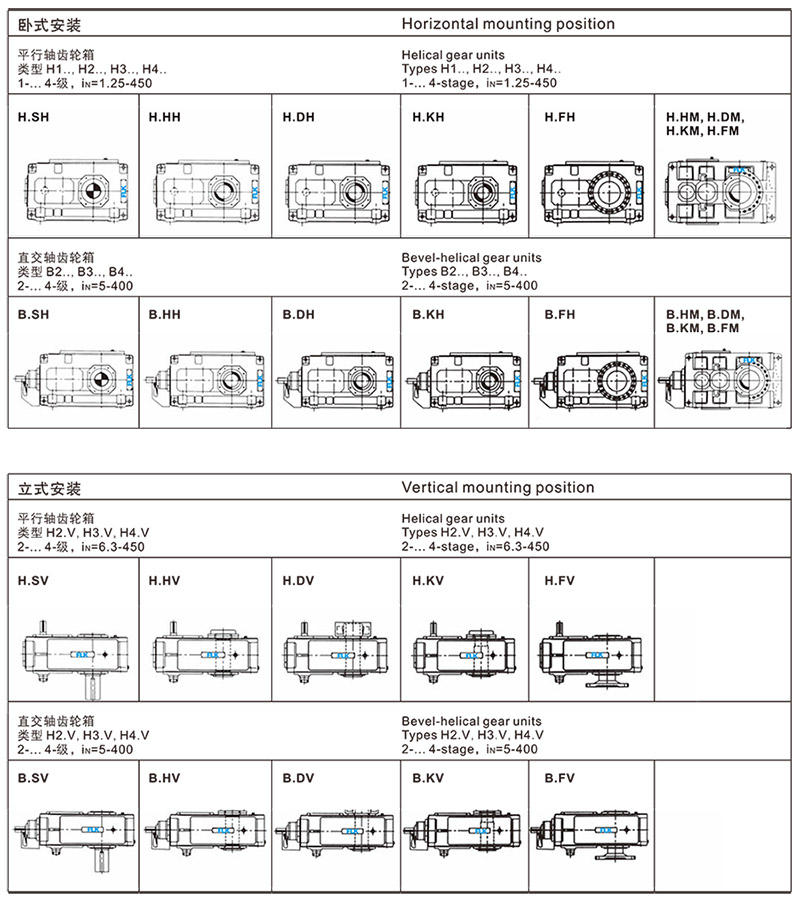

Montageposition

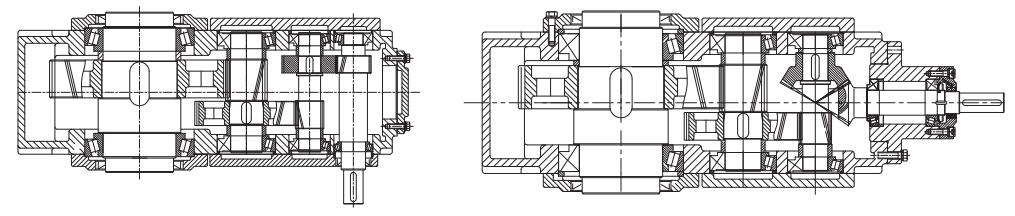

Strukturzeichnung

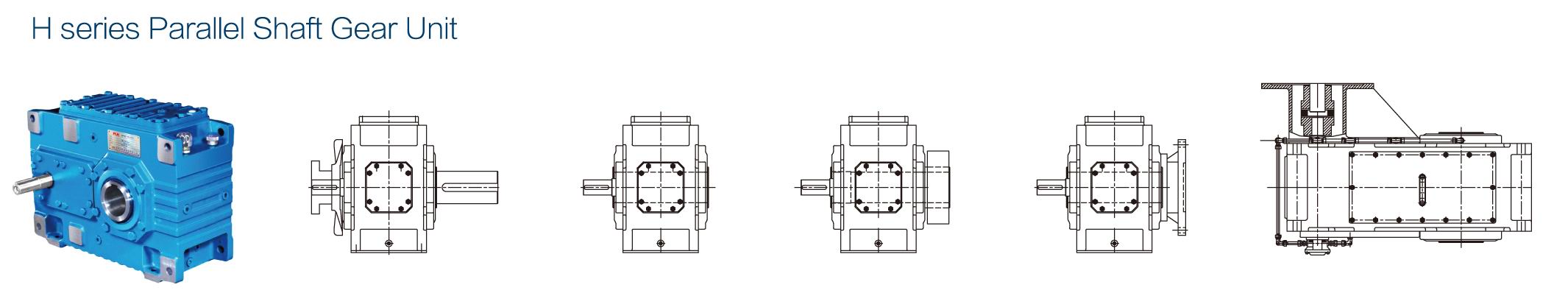

MODULARES DESIGN

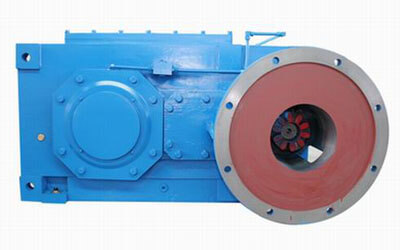

PRODUKTBILDER

H3HV12 Parallelwellen-Stirnradgetriebe

H3SH6 Parallelwellen-Stirnradgetriebe

H3SH12 Stirnraduntersetzungsgetriebe

Anwendung:

Parallelwellengetriebe der H-Serie werden häufig in der Leichtindustrie, der Lebensmittel-, Bier- und Getränkeindustrie, der chemischen Industrie, Rolltreppen, automatischen Lagereinrichtungen, im Baugewerbe, im Maschinenbau, in der Eisen- und Stahlmetallurgie, in der Papierherstellung, in Holzwerkstoffmaschinen, im Automobilbau und in der Tabakindustrie eingesetzt Maschinen, Wasserschutz, Druck und Verpackung, Pharma, Textil, Baustoffe, Logistik, Futtermittelmaschinen, Umweltschutz und andere Bereiche.