Choosing the right gear reducer

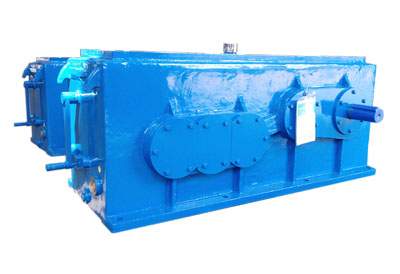

A gear reducer is a mechanical transmission device that connects a motor to a driven load. It is also known as a gearbox. It allows you to modify the torque and speed between a motor and a load. Reduction gear assemblies are made up of series of gears. The gear reduction ratio (the ratio of the number of teeth between input and output shafts) is also known as the transmission ratio.

What is the selection criteria for choosing a gear reducer?

Before buying a gearbox reducer, it’s important to take several factors into account.

A gearbox reducer is used to adapt the characteristics (torque and speed) of the input and output axis of a mechanism. This is why you have to know the torque and rotation speed.

It is therefore appropriate to ask yourself about the torque first and foremost. A reducer increases the torque of your motor and thus allows a receiving member to rotate under the impact of a new torque. Gear reducer manufacturers sometimes indicate the minimum and maximum torque (expressed in newton meters, N.m) that can be supported by each of their products. The torque density varies according to the gear reducer. For example, planetary gearboxes have a high torque density.

The other purpose of a gear reducer is to reduce the motor speed and we recommend that you take into account the ideal reduction ratio for your use. Based on the rotational speed of your motor, the reduction ratio is used to determine the output rotational speed. This information is also indicated by manufacturers on their product pages. It is given in revolutions per minute.

Lastly, you should ask yourself what kind of gearbox reducer assembly is most appropriate for your application. The input and output shafts of your gear reducer can be coaxial, parallel-shaft or orthogonal. This depends on your intended use.

What are the different types of gear reducers?

There are four main types of gearbox reducers: planetary gear reducers, worm gear reducers, gear train gear reducers and bevel gear reducers. Each gear reducer has its advantages and disadvantages. You will have to choose the one that’s the most adapted to your intended use.

For example, if you are looking for a good level of efficiency, perhaps you should consider a planetary gearbox rather than a bevel gear reducer.

The main types of gear reducers:

- planetary gearboxes

- worm gear reducers

- gear train gear reducers

- bevel gear reducers

When should you use a planetary gearbox?

One of the main characteristics of a planetary gearbox is the coaxial assembly. This type of assembly means that planetary gearboxes are compact.

The advantages of planetary gearboxes include their compact size, high efficiency, low clearance and high torque to weight ratio. On the other hand, their complex and costly design requires specialized maintenance.

We recommend the use of a planetary gearboxes for applications requiring strong accelerations (robotics) as well as for applications with a slow speed but high torque (industrial rotary furnaces). They are also widely used for machining centers and other machine tools, and mobile machinery used in public and agricultural works.

Main advantages

- up to 50% more torque than planetary gearboxes with equivalent spur gears

- better load distribution, which increases service life

- quieter operation

- low backlash not exceeding 2 arc-minute of play

When should you use a worm gearbox reducer?

Worm gearbox reducers have perpendicular input and output shafts. They are generally used for applications requiring a very high transmission ratio.

The mechanism of worm gear reducers is non-reversible. This means that the worm wheel cannot drive the worm. The advantage of this non-reversible mechanism is that it ensures a greater level of security for the system.

Worm gear reducers are less expensive than planetary gearboxes and are also quieter. Worm gear reducers do not vibrate, so they generate little noise and are more comfortable to use.

However, like planetary gearboxes, worm gearbox reducers heat up quickly due to how compact they are. They also have a variable performance level. You can however improve the performance by combining your worm gear reducer with other gearboxes and gear trains.

We recommend that you choose this type of technology for conveyors, winches and handling.

When should you use a gear train gearbox reducer?

Gear train gear reducers with parallel axes are generally used for applications requiring a lot of power, such as conveyors.

The simplicity of their technology will allow you to save on maintenance costs. Additionally, gear train gear reducers have a very high performance level, close to 1.

They have a low reduction ratio per gear train.

When should you use a bevel gearbox reducer?

Bevel gear reducers’ main characteristic is their angular bell crank, which allows the user to change the machine’s rotation system. This will allow you to switch from a transverse rotation system to a longitudinal rotation system.

Bevel gear reducers are compact. They are also robust and can handle a lot of power. As such, if you need a high torque we recommend that you choose this technology. The robustness of their teeth allows you to use them with three-phase asynchronous motors, or synchronous or asynchronous servomotors.

Bevel gear reducers are quiet, making using them pleasant to use. Additionally, they offer a high performance level and are energy efficient. Their performance level remains lower than planetary gearboxes however. Bevel gear reducers are also very expensive and require difficult maintenance.

Bevel gear reducers are generally used for high-powered conveyors, but also for mobile machinery used in agricultural or public works.

How to calculate the dimensions of your gear reducer?

In order to calculate the dimensions of your gear reducer, you will need to choose the right shaft. There are three different shaft orientations: orthogonal, coaxial and parallel.

If a gear reducer has an orthogonal shaft orientation, the input and output shafts are perpendicular. This is often the case for bevel gear reducers and worm gear reducers. Orthogonal shaft orientation is also used in industrial installations and differential automotive bridges.

If a gear reducer has a coaxial shaft orientation, the input and output shafts are aligned. This is the case, for example, for planetary gearboxes or gear reducers used in engines and turboprop engines used in the aeronautic industry.

If a gear reducer has a parallel shaft orientation, the input and output shafts are parallel.

Measuring The Dimensions Of Your Gear Reducer

To determine the size of your gear reducer, you must first choose the proper shaft. There are three shaft orientations to choose from: orthogonal, coaxial, plus parallel.

The input and output shafts of a gear reducer are perpendicular if it has an axial shaft orientation. This is often the case with bevel and worm gear reducers. In addition to industrial applications, orthogonal shaft alignment is employed in differential automobile bridges.

The inlet and outlet shafts of a gear reducer are aligned if it has a coaxial shaft arrangement. This is true, for example, of planetary gearboxes or gear reducers used during aeronautical engines and turboprop engines. The input and output shafts of a gear reducer are parallel if it has a parallel shaft orientation.

Conclusion

A gear reducer plays a crucial role in the efficiency and effectiveness of the overall mechanism. Hence, it’s important to not only find the right gear reducer but also find a provider that offers high-quality products. At FLK Drive Transmission, we offer high-quality, precision-engineered power transmission solutions to the global industry. For more information, contact us today!