Unit Gear Elevator Bucket

Parameter teknis:

| Model yang tersedia | B3SH04 ~ B3SH18, B3HH04 ~ B3HH18, B3DH04 ~ B3DH18 dengan drive bantu k seri heliks motor diarahkan bevel |

| Perbandingan | 16 ~ 400 |

| Daya input | 5.4 ~ 2398 kw |

| Torsi maks | 6.7 ~ 265 KN.M |

Keterangan

Drive lift ember dapat diterapkan dalam mekanisme mengemudi Conveyor Belt, troli konveyor, conveyor scraper, konveyor ember, konveyor troli, konveyor sekrup, konveyor getaran dan berbagai jenis konveyor.

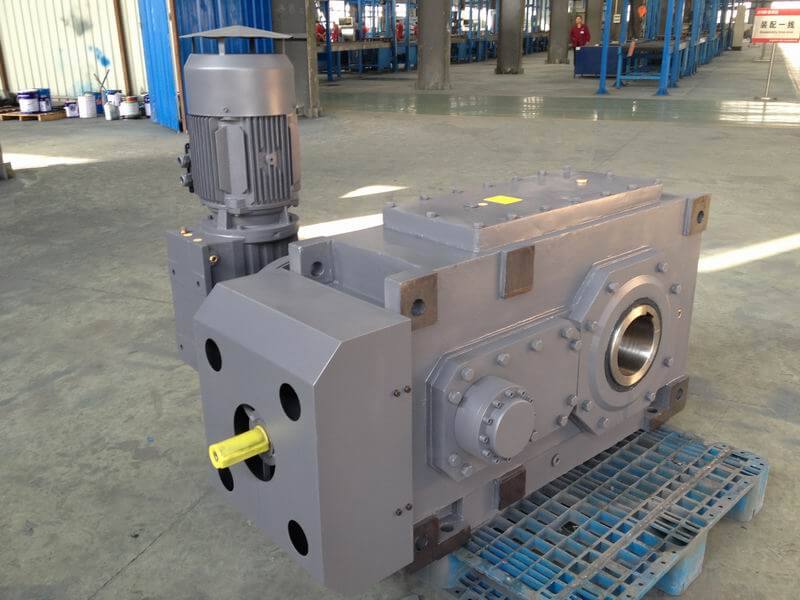

Bucket Elevator Series Gear Box adalah kotak roda gigi yang dirancang khusus sesuai dengan situasi aplikasi dan karakteristik transmisi conveyor bucket. Ini adalah produk pencocokan pilihan pertama untuk produsen lift ember domestik dan asing.

Elevator bucket berfungsi untuk mengangkut massa besar secara vertikal dari bahan curah ke ketinggian yang berbeda tanpa membuat debu, lalu buang. Tinggi yang harus diatasi sering lebih dari 200 meter. Bobot yang harus dipindahkan sangat besar.

Elemen pembawa dalam lift ember adalah untaian rantai sentral atau ganda, rantai tautan, atau sabuk tempat ember terpasang. Drive terletak di stasiun atas. Fitur yang ditentukan untuk drive yang ditujukan untuk aplikasi ini mirip dengan yang untuk konveyor sabuk naik yang tajam. Elevator bucket membutuhkan daya input yang relatif tinggi. Drive harus dimulai dengan lembut karena daya awal yang tinggi, dan ini dicapai dengan cara kopling cairan di kereta drive. Unit gear heliks bevel biasanya digunakan untuk tujuan ini sebagai drive tunggal atau kembar pada bingkai dasar atau dasar ayunan.

Bucket elevators require high drive power depending on the bulk material and the conveyor height. Our standardized bucket elevator gear unit drive solution ensures that you have the power you need.

Karakteristik

- Gearbox yang kuat dengan konsep unik yang dirancang untuk kondisi beban penuh.

- Desain ekologis yang sangat baik menambah kilau pada citra merek Anda.

- Drive utama dan tambahan dapat secara otomatis diaktifkan melalui kontrol listrik dan dikendalikan dari jarak jauh untuk pemasangan, debugging, dan penggunaan yang mudah.

- Desain terintegrasi transmisi utama / tambahan, struktur kompak dan keandalan tinggi.

- Backstop berkualitas tinggi dan kopling overrunning dipilih, dengan volume kecil dan faktor keamanan tinggi, yang dapat memenuhi kondisi kerja transmisi tambahan beban penuh.

- Hingga 93% dari desain modular, produksi internasional, produksi yang lebih cepat dan siklus logistik.

- Kepadatan daya yang lebih tinggi dapat menghemat ruang pemasangan peralatan Anda dan struktur keseluruhan lebih kompak.

- Keandalan yang tinggi dan umur desain yang panjang dapat secara efektif mengurangi biaya penggunaan dan biaya pemeliharaan Anda.

- Tanpa konfigurasi transmisi tambahan dan beberapa output dan rakitan, dapat memenuhi berbagai kasus.

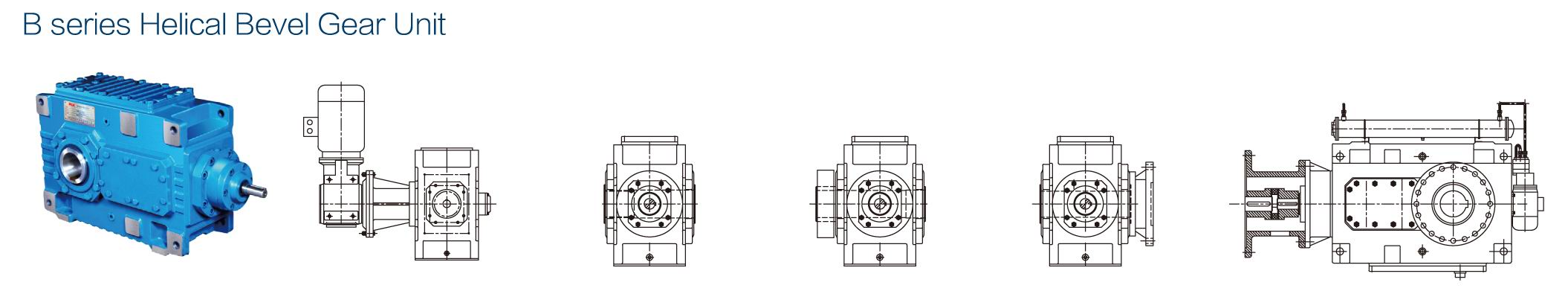

Bentuk produk

- Tahap Transmisi: Tahap 3

- Pemasangan: Dipasang horizontal (dengan atau tanpa drive tambahan)

- Output paralel: poros padat, poros berongga (kunci datar, disk menyusut, spline involute), poros padat splined, poros flensa

- Output poros padat terkunci (Jenis: B3S…)

Keyway Hollow Shaft Output (Jenis: B3H…)

Susut Disc Hollow Shaft Output (Jenis: B3D ...)

Model

- Drive Utama: Jenis: B3 (S/H/D)…

Ukuran bingkai: 4, 5, … 17, 18

Rasio: 25, 28, … 63, 71 - Drive tambahan: Jenis: KF… (Output poros padat dengan flensa pemasangan)

Ukuran bingkai: 37, 47, … 157, 167

Opsi utama

- Penghalang

- Cengkeraman freewheel (kopling overrunning)

- Tangki oli kompensasi pelumasan

- Pompa oli pelumas paksa

- Kipas pendingin, kumparan pendingin

- Perangkat pendingin eksternal

- Kopling cairan (kopling hidrolik)

Data teknis

- Jenis: Bevel Helical Gear Unit FLK Drive

- Ukuran: 15 ukuran dari 04 hingga 18

- Jumlah Tahapan Gear: 3

- Peringkat Daya: 10 hingga 1.850 kW (daya drive tambahan dari 0,75 hingga 37 kW)

- Rasio transmisi: 25 – 71

- Torsi Nominal: 6,7 hingga 240 knm

- Posisi pemasangan: Horizontal

Desain Modular

Gambar produk

Aplikasi:

- Lift ember

- Konveyor ember

- Konveyor Scraper

- Kerekan

- Winches

- Lift barang

- Lift penumpang

- Eskalator