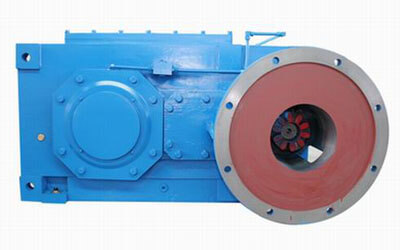

H series Parallel Shaft Helical Gearbox

기술 매개 변수 :

| 사용 가능한 모델 | H1SH03~H4SH26 |

| 비율 | 1.25~450 |

| 입력 전원 | 5.5 ~ 4400 kW |

| 최대 토크 | 2.9~900 kN.m |

설명

H Series industrial helical parallel shaft gear units are high-quality gearboxes for heavy-duty industrial applications. All mechanical parts are analyzed with state-of-the-art software to guarantee their reliability. We also offers tailored solutions for specific applications.

High efficiency H series helical parallel shaft industrial gearboxes have been introduced to meet the requirements of today’s demanding applications in the medium and heavy-duty sector of the power transmission market. The purpose of using the parallel shaft gearbox is to reduce the speed and increase the torque. It is suitable for high-speed axle speed not more than 1500 rpm, gear drive circumferential speed not more than 20 m/s, working environment temperature is -40℃~+45℃. The gearboxes are compact, totally enclosed and are designed for direct mounting to ensure highest precision positive drive and permanent alignment minimizing space requirement and layout problems. H series parallel shaft helical gearbox offers unlimited installation flexibility.

형질

- 최적화 된 모듈 식 디자인을 채택하십시오.

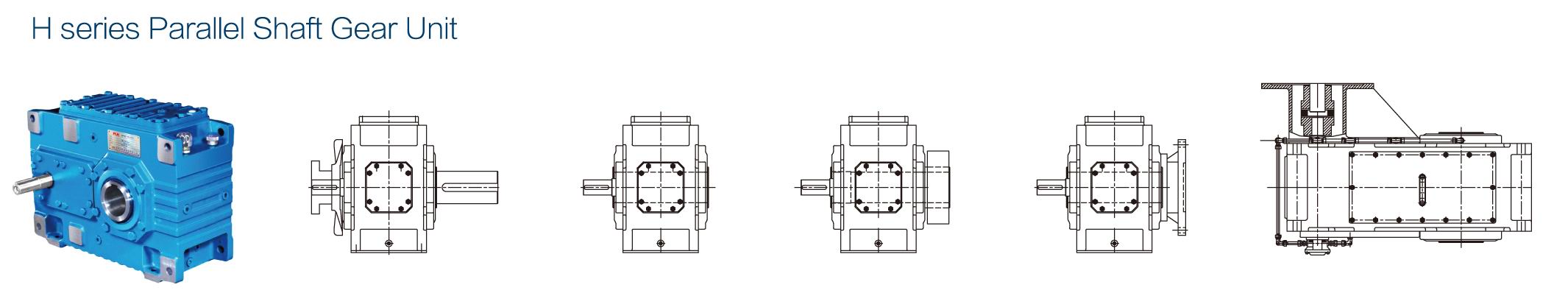

- Parallel shaft output form.

- 변속기 토크 분포 곡선은 우수하며 무거운 하중 조건에 적합합니다.

- 고급 연삭 기술 및 형상 수정 기술을 채택하는데, 이는 베어링 용량이 높고 안정적인 작동 및 저음이 적습니다.

- 박스 본체는 감속기의 기계적 강도 및 지진 성능을 향상시키기 위해 고품질 캐스팅으로 만들어졌습니다.

- 수많은 장착 옵션을 사용할 수 있습니다.

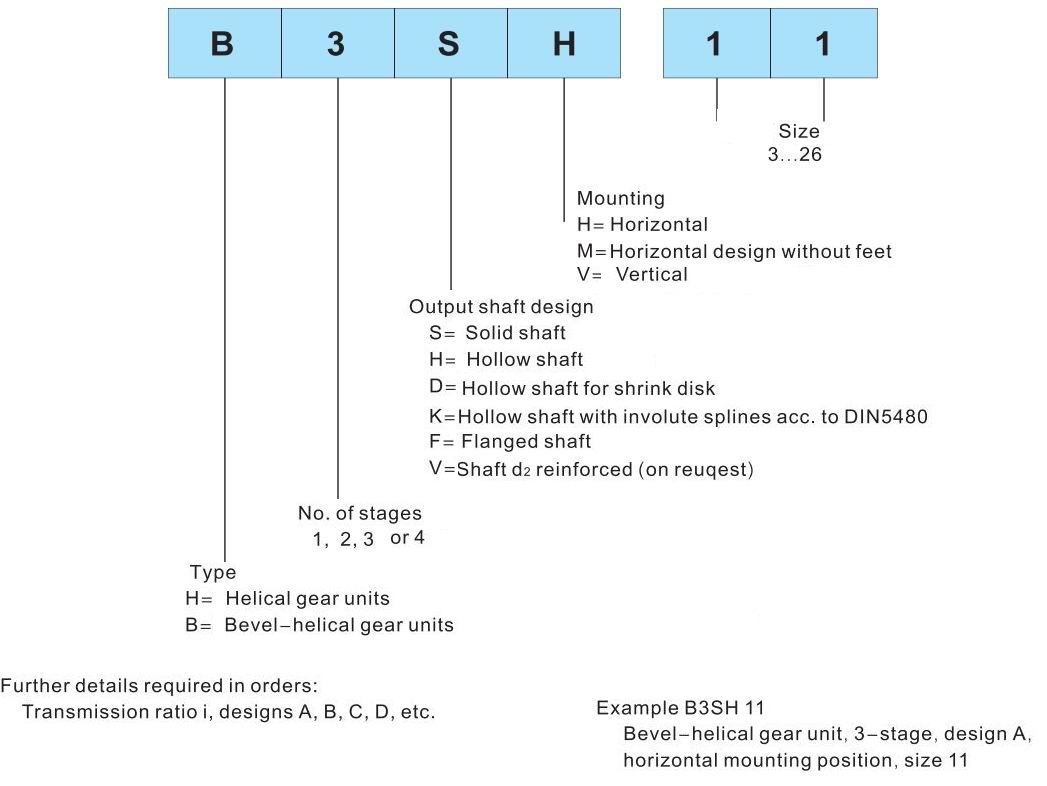

제품 양식

- Transmission Stage: single stage, 2 stage, 3 stage, 4 stage.

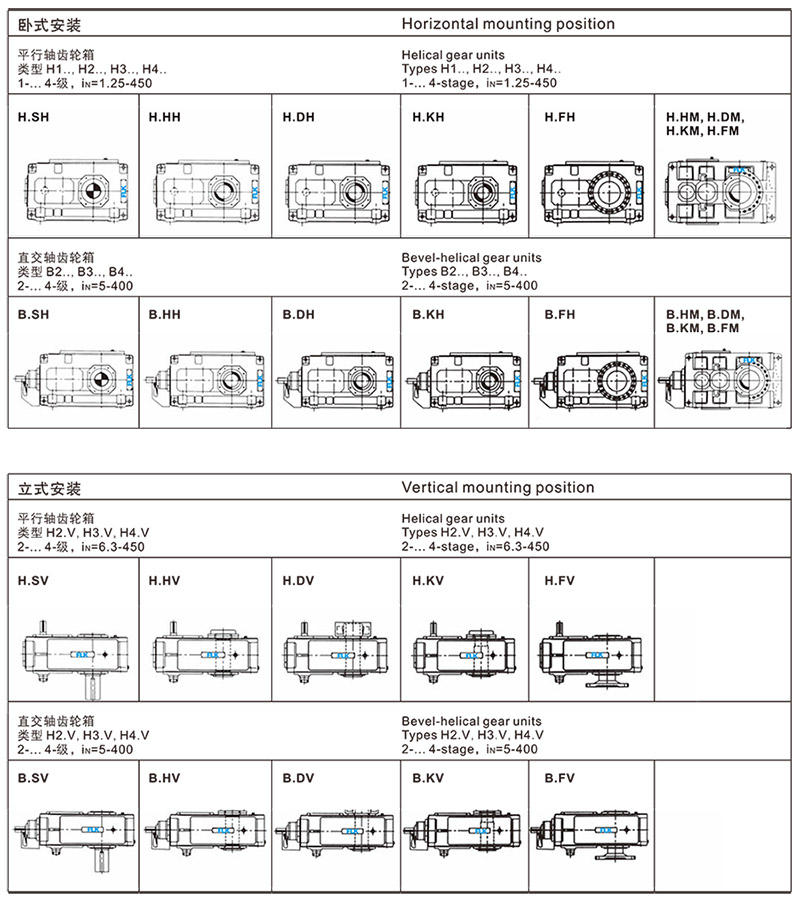

- 장착 : 수평 장착, 수직 장착

- 평행 출력 : 솔리드 샤프트, 중공 샤프트 (플랫 키, 수축 디스크, Involute Spline), 스플라인 고형 샤프트, 플랜지 샤프트

- Configuration options: With auxiliary tank, with oil pump, with cooling fan, with backstop, with hydraulic coupling, with gear unit swing-base

기술 데이터

- Size: H1SH03~H4SH26

- Technical Data(kN·m): 2.9~900

- Gear Ratio: 1.25~450

- Input Power(kW):5.5~4400

- Housing material: HT250 high-strength cast iron

- Housing hardness: HBS190-240

- Gear material: 20CrMnTi alloy steel, other materials requested: 17CrNi2Mo, 20CrNi4A

- Surface hardness of gears: HRC58-62

- Gear core hardness: HRC33-40

- Input / Output shaft material: 42CrMo alloy steel

- Input / Output shaft hardness: HRC25-30

- Heat treatment: tempering,cementiting,quenching.etc.

- Machining precision of gears: accurate grinding, 6-5 Grade

- Noise (MAX): 60~68dB

- Lubricating oil: GB L-CKC220-460, Shell Omala220-460

- Temp. rise (MAX): 40°C

- Efficiency: 94%~96% (depends on the transmission stage)

- Temp. rise (Oil)(MAX): 50°C

- Backlash: ≤20Arcmin

- Vibration: ≤20µm

- SAME DIMENSION AS Flender

사용 가능한 모델

| H Series | 비율 | B Series | 비율 |

| H1 (1 Stage parallel shaft gearbox) | 1.25~5.6 | – | – |

| H2 (2 Stage parallel shaft gearbox) | 6.3~28 | B2 (2 Stage helical bevel gearbox) | 5~18 |

| H3 (3 Stage parallel shaft gearbox) | 22.4~112 | B3 (3 Stage helical bevel gearbox) | 12.5~90 |

| H4 (4 Stage parallel shaft gearbox) | 100~450 | B4 (4 Stage helical bevel gearbox) | 80~400 |

| 전송 단계 | 비율(i) | 모델 |

| H1 | 1.25 – 5.6 | H1SH3, H1SH5, H1SH7, H1SH9, H1SH11, H1SH13, H1SH15, H1SH17, H1SH19 |

| H2 | 6.3 – 28 | H2SH4, H2SH5, H2SH6, H2SH7, H2SH8, H2SH9, H2SH10, H2SH11, H2SH12, H2SH13, H2SH14, H2SH15, H2SH16, H2SH17, H2SH18, H2SH19, H2SH20, H2SH21, H2SH22, H2SH23, H2SH24, H2SH25, H2SH26 |

| H3 | 25 – 112 |

H3SH4, H3SH5, H3SH6, H3SH7, H3SH8, H3SH9, H3SH10, H3SH11, H3SH12, H3SH13, H3SH14, H3SH15, H3SH16, H3SH17, H3SH18, H3SH19, H3SH20, H3SH21, H3SH22, H3SH23, H3SH24, H3SH25, H3SH26 |

| H4 | 90 – 450 | H4SH5, H4SH6, H4SH7, H4SH8, H4SH9, H4SH10, H4SH11, H4SH12, H4SH13, H4SH14, H4SH15, H4SH16, H4SH17, H4SH18, H34H19, H4SH20, H4SH21, H4SH22, H4SH23, H4SH24, H4SH25, H4SH26 |

유형 및 지정

장착 위치

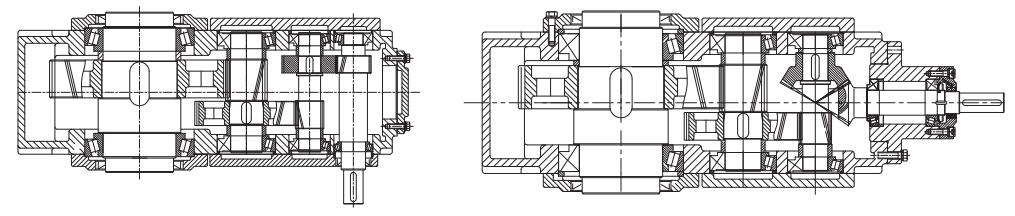

구조 도면

모듈 식 디자인

제품 사진

H3HV12 Parallel Shaft Helical Gear Box

H3SH6 Parallel Shaft Helical Gearbox

H3SH12 Helical Reduction Gear Box

애플리케이션:

H series parallel shaft gearboxes are widely used in light industry, food, beer and beverage, chemical industry, escalators, automatic storage equipment, construction, machinery, iron and steel metallurgy, paper-making, wood-based panel machinery, automobile manufacturing, tobacco machinery, water conservancy, printing and packaging, pharmaceutical, textile, building materials, logistics, feed machinery, environmental protection and other fields.