What are the advantages of Helical Gearmotors?

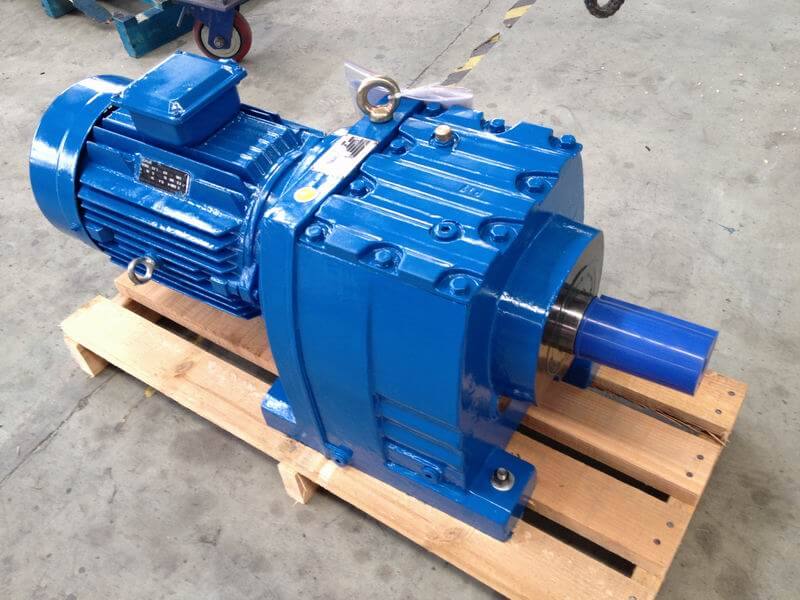

FLK Drive offers a wide range of helical gearmotors that are designed to be easy maintenance and provide long service life in the demanding industrial applications nowadays. Our helical Gearmotors series are available in a wide variety of sizes/ratios and are designed to be easily interchanged with many European style gearmotors. Currently we offer 4 kinds of helical gearmotors that are available in a variety of sizes and ratios , they are FLK R series inline helical geared motor, K series helical bevel geared motor, F series parallel shaft helical geared motor and S series helical worm geared motor.

Each Gearmotor is designed to be easily interchanged with many European-style gearmotors while offering unmatched reliability. These units come standard with features such as Anti-friction bearings for optimum load capacity and long life, high strength cast iron housings, and both a high cross-section modulus design and rugged monobloc design for maximum rigidity.

The advantages of Helical Gearmotors:

- The angled teeth work more gradually, allowing for smoother and more silent gear operation when compared to spur gears or toothed wheels.

- Helical gears last longer and are ideal for high-load applications, since they have a higher amount of teeth in contact.

- Load is at all times distributed among several axes, which produces less wear.

- They can transfer motion and power both among parallel and straight-angle axes.

R series inline helical gearmotor:

Our helical gearmotors achieve a very high torque density and long service life. These gearmotors are specially designed for great performance and reliability, and offered in a wide range of torques and gear ratios are offered to best fit the needs of your applications. These gearmotors are compatible with many critical mechanical systems.

Power ratings from 0.05 to 433 HP

Ratios from 1.3 to 23,401

Output torques to 490,641 lb-in

Typical applications: Conveyors, material handling, steel mills, paper mills.

K series helical bevel gearmotor:

Each helical bevel gearmotor is designed for wear-free operation, allowing for a long service life. These gearmotors feature gear efficiencies of more than 90% in both directions of rotation within the system. As with other FLK Gearbox Company products, these gearmotors are also very compact and they boast a high power density, to better meet the needs of your machinery. These products are also resilient enough to be operated in a wide range of ambient temperatures and are designed to work in many mechanical applications, while operating at high levels of efficiency.

Power ratings from 0.05 to 615 HP

Ratios from 3.98:1 to 24,353:1

Output torques to 442,500 lb-in

Typical applications: Conveyors, material handling, steel mills, paper mills.

F Series parallel shaft helical gearmotor:

FLK F series Parallel shaft gearmotors are designed for use in a variety of mechanical systems such as industrial conveyors, material handlers, steel mills, and more. Each unit is designed to be slim and compact to ensure the best fit in many critical spaces that demand precision positioning and quality.

Power ratings from 0.05 to 336 HP

Ratios from 3.77 to 29,211

Output torques to 159,300 lb-in

Typical applications: Conveyors, material handling, steel mills, paper mills.

S Series helical worm gearmotor

FLK S series helical worm gearmotors utilize an helical/helical-worm combination, making these units more efficient than normal helical-worm gear units. Due to their outstanding efficiency, these drives can be used in every industrial sector and tailored to individual torque and speed requirements. The reduction ratios afforded by the helical-worm gear stage and the low noise levels during operation make these gearmotors ideal low-cost solutions for simple applications.

Power ratings from 0.05 to 46 HP

Ratios from 3.97 to 33,818

Output torques to 35,400 lb-in

Typical applications: Drives in theater applications, adjustment drives, presses, rotary tables, and corner transfer units.