Helical gear motors provide rotary motion using distinctive helical gears, differing from traditional spur gears. These motors offer quieter, smoother operation ideal for low noise, high-speed applications. Types include inline, parallel shaft, helical bevel and helical worm, each with specific industrial uses. Their design ensures longevity, reduced noise and efficiency, but regular maintenance is essential.

Introduction to Helical Gear Motors

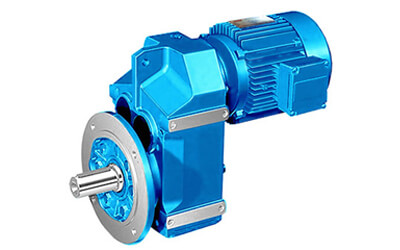

Helical gear motors are a type of electric motor that provide rotary motion and torque. The distinctive feature of these motors is the use of helical gears, a system that differs from spur gears or bevel gears. This difference is pivotal in the operational efficiency and functionality of the gear motors.

Understanding the Mechanism

The key element of a helical gear motor is the helical gear. Unlike spur gears, where the teeth are straight and positioned parallel to the axis of rotation, helical gears have teeth that are cut at an angle to the face of the gear. When two teeth on a helical gear system engage, the contact starts at one end of the tooth and gradually spreads along the tooth. This characteristic provides smoother and quieter operation than spur gears, making helical gear motors ideal for applications requiring low noise and high speed.

Types of Helical Gear Motors

Inline Helical Geared Motors:

The inline helical geared motors are designed based on module, which bring many difference kinds of combinations, mounting types, and structure designs. The detail classification of ratio can meet various of working condition. They are widely used in light industry, food, beer and beverage, chemical industry, escalators, automatic storage equipment, construction, machinery, iron and steel metallurgy, paper-making, wood-based panel machinery, automobile manufacturing, tobacco machinery, water conservancy, printing and packaging, pharmaceutical, textile, building materials, logistics, feed machinery, environmental protection and other fields.

Parallel Shaft Helical Gear Motors:

As the name suggests, these gear motors have shafts that are parallel to each other. They are well-known for their robustness, high endurance, and capability to transmit high torque. They are often used in conveyor systems and material handling industries.

Helical Bevel Gear Motors:

These motors are a combination of bevel and helical gears. They are known for their high efficiency and compact design. They are typically used in food processing, textile, and packaging industries.

Helical Worm Gear Motors:

These motors use a combination of helical and worm gears. They are appreciated for their low noise levels, high shock tolerance, and are often used in bottling and conveyor systems.

Advantages of Helical Gear Motors

Helical gear motors provide several benefits that make them a superior choice for many industrial applications. The angled teeth engage more gradually than spur gears which results in smoother transitions and less noise. This makes helical gears particularly suited for high-speed, high-torque applications. Furthermore, they have a longer lifespan due to reduced wear and tear.

Applications of Helical Gear Motors

Helical gear motors are incredibly versatile, finding use across a wide range of applications and industries. They’re frequently seen in:

- Material Handling: In conveyor systems, these motors provide the necessary torque and speed to move goods efficiently.

- Food Processing: They’re used in machinery for mixing, cutting, and packaging, where a quiet, high-torque motor is beneficial.

- Chemical Industry: In equipment such as mixers, agitators, and pumps, these motors provide reliable, high-performance operation.

- Automotive Industry: They are used in different parts of the vehicle for precise, low-noise operation.

Maintenance of Helical Gear Motors

Maintenance is a crucial aspect of keeping helical gear motors operating effectively. This involves regular inspection for signs of wear, ensuring adequate lubrication of gears, and the timely replacement of worn-out parts. Maintenance helps prolong the lifespan of the gear motor and ensures its efficient operation.

Conclusion

Helical gear motors are an invaluable component in many industrial applications due to their high efficiency, smooth operation, and versatility. Their angled teeth design enables gradual engagement, resulting in reduced noise and smoother operation than other types of gear systems. These attributes make them particularly suited for high-speed, high-torque applications where noise must be minimized.

Despite their inherent advantages, appropriate maintenance and upkeep are crucial to maximize their operational efficiency and lifespan. From conveyor systems in material handling industries to precise operations in the automotive sector, helical gear motors are an integral part of modern industry. Their widespread adoption and versatile application reflect their significance and effectiveness in today’s mechanized world.

FLK Drive is a professional manufacturer of helical geared motors, parallel shaft gearboxes, single stage gearboxes, two stage gearboxes, three stage gearboxes, four stage gear reducers, coaxial gearboxes, speed reducers, helical bevel geared motors, industrial gearboxes, heavy duty planetary gear units, hoist gear units and electric motors from China with over 20 years manufacture experience. We provides one-stop power transmission drive solutions to clients worldwide.